ACS 6000 - The world’s most successful MV multidrive

Date: Mar 09, 2025 Views: 863

ABB’s ACS 6000 medium voltage drive provides the optimum solution for applications where high power and maximum reliability is required. Since its introduction, the ACS 6000 has gained an excellent reputation for high quality and reliability. As a result ABB has worldwide the largest installed base of medium voltage multidrives incorporating the latest technology.

ABB’s ACS 6000 is a modular drive designed for the most demanding single-motor or multi-motor applications. The optimum configuration for each application is reached by combining the modules with minimum engineering effort resulting in lower investment costs and a smaller footprint. It is available with five sizes of inverter modules (3, 5, 7, 9 and 11 MVA).

Several motors can be linked to the ACS 6000 via the common DC bus, enabling multi-machine operation with only one multidrive converter. A multidrive, common DC bus converter principle offers a solution with optimum efficiency.

The ACS 6000 medium voltage drive can be used in a wide range of industries.

.jpg)

The ACS 6000 medium voltage drive for speed and torque control of 3 – 27 MW induction or synchronous motors is a member of the ABB AC drives product family. It offers a number of unique key features.

Powerful performance

Fast and accurate process control in combination with low energy consumption results in top performance. The motor control platform of the ACS 6000 is based on ABB’s award-winning Direct Torque Control (DTC) technology. DTC provides the highest torque and speed performance ever achieved in medium voltage drives. As a result, control of the drive is immediate and smooth under all conditions.

High efficiency and reliability

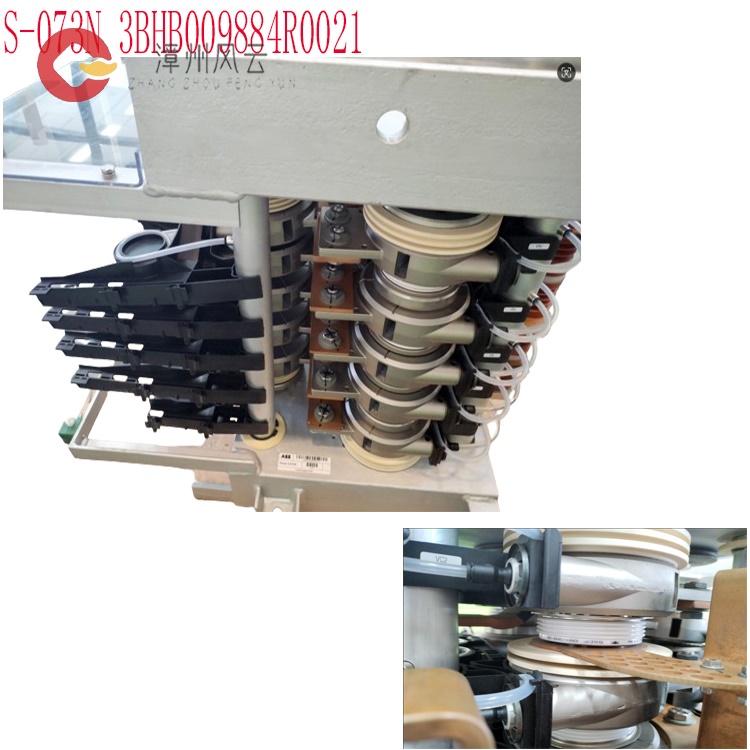

The ACS 6000 uses a revolutionary power semiconductor switching device known as IGCT (Integrated Gate Commutated Thyristor) researched and designed by ABB. The use of IGCTs results in a less complex, more efficient and reliable high-power medium voltage drive, minimizing operating and maintenance costs.

High availability

Maximum reliability and short repair time results in a drive with high availability.

Optimized energy flow

The common DC bus allows several motors to be connected to the same DC bus, providing an optimized energy flow.

The braking energy generated in one motor can be transferred to other inverters via the common DC bus without power consumption from the supply network. Due to the near unity power factor throughout the whole speed range the energy efficiency is optimal.

Flexible

Optimum configuration

The modular design of the ACS 6000 allows the optimum configuration of any drive system. Each configuration, consisting of well-proven and certified modules, exactly fits the customer’s requirements.

Smooth system integration

The ACS 6000 integrates easily into the industrial environment because it can be optimally configured for single-motor and multi-motor applications without additional control equipment. The high power density and compact design and the drive’s communication abilities minimize the overall installation and operational costs.

The drive can be connected to the network through one or several transformers depending on power and harmonics requirements. Even a transformerless solution is available for certain applications

![]() product-data-sheet-ams-6300-sis-ams-en-105046.pdf

product-data-sheet-ams-6300-sis-ams-en-105046.pdf

Related product recommendations:

S-093M 3BHB009885R0013

S-097H 3BHB009885R0052

S-093M 3BHB009885R0063

S-093H 3BHB009885R0005

S-093R 3BHB009885R5311

KUC755AE105 3BHB005243R0105

S-073N 3BHB009884R0021

S-097H 3BHB009885R0052

S-093H 3BHB030478R0309

S-053M 3BHB012897R0003

More......

RELATED ARTICLE

Address

Room 205, Office Building, No.1 Chaoyang North Road, Longwen District, Zhangzhou City, Fujian Province

fengyunfadacai@qq.com

Sales consultant

Miss.Green

+86 15860249102